The adoption of electric vehicles (EVs) is gaining pace worldwide, bringing the charging infrastructure into focus. to date, charging points for EVs have been plug—in solutions, which work but are not very convenient. More recently, fast charging plug-ins have been introduced, which currently represent only a fraction of the installed base. However, one big drawback is the lack of standard EV universal plug (nowadays, at least three different plug types are widespread). The next and final step in the evolution of EV charging is wireless charging: there is a worldwide accepted standard, and it is perceived as a key enabling technology for autonomous driving.

The European Union is launching new initiatives aimed at transforming industries in Europe which are world leaders in innovation and digitization. Developing a sustainable road transport infrastructure is a key element in these initiatives, evidently disturbing the car industry. Battery charging is possible either by recharging points, or whilst driving on electric tracks in the roads. this leads to smaller and lighter batteries. Sweden, Germany and France started their own pilot projects with electric roads using overhead lines to charge trucks.

As technology improves, drivers expect more miles per charge, greater selections and better prices. However, EV drivers constantly have ‘range anxiety’, wondering if only a 400 km range for a fully-charged EV, for example, would be enough. This way they wouldn’t need to change their habits inherited from combustion vehicles. Today’s trend for larger battery packs in order to mitigate range anxiety cannot be the final solution.

With lithium as a scarce resource worldwide, nowadays it can be considered as the ‘new oil’, making us wonder if the lithium battery demand will always cover the demand for batteries. Lithium batteries’ demand has increased 20% in the past ten years and is looking to set to double — or even triple — by the mid-2020s, increasing the presence of a lithium supply crisis between 2023 and 2025.

Despite all efforts, the pace of increasing lithium batteries production will not close this gap. there seems tot be a good chance of a production flow by joining all big lithium mining companies committed to a rapid expansion. In response to the increased demand for EV batteries, the global lithium production increased by 12% in 20l6. Nonetheless, it is still difficult to assess the outlook for global production by the late 2020s.

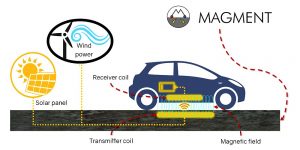

Moreover, stationary fast-charging would require a still longer amount of time. Dynamic wireless charging, powered by stored solar energy, presents a futuristic but all—possible vision thanks to our technological innovations. With a 70% reduction on battery needs, EVs will drive longer distances despite smaller batteries, keeping vehicles affordable. ‘Solar roads’, which transfer energy through coils embedded in magnefizable concrete roads, charge the battery to assure a round-the-clock energy flow. Designing the final e-mobility trend is our vision. Addifionally, used car batteries can be re-used for a second life as part of the battery storage system.

MAGMENT magnetizable concrete

MAGMENT magnetizable concrete materials — either cement- or asphalt-based — is a patented technology displaying the mechanical properties of conventional concretes, thus making it fully compatible with materials currently used in road pavements. This overcomes one of the biggest hurdles for the adoption of pavement-based charging pads and dynamic charging systems. Just like any other concrete, MAGMENT can come in pre-cast panels or otherwise cast in situ. This makes its application fully compatible with conventional road construction practices.

MAGMENT concretes are equally suitable for both stationary and dynamic, high-efficient wireless charging. Their load-bearing properties allow not only wireless charging of electric passenger cars, but also of buses, vans and lorries. Due to its lower density and cost compared to conventional magnetic materials (reduced weight), the MAGMENT concrefe material could also be attractive for use in the EV pick-up coils.

The magnetic properties of MAGMENT concrete are due to embedded ferrite particles used as magnetic aggregafes. These ferrite parficles are obtained, but not limited to, recycled material from the ferrite industry and from the rapidly growing amount of electronic waste. It is worth noting that, unlike lithium, all chemical elements needed to produce this material (iron, manganese, zinc, calcium and aluminum) belong to the most abundant metals on Earth. therefore, and due to its low cost, magnefizable concretes have the potential for a truly widespread usage. this is especially driven by autonomous inductive charging for self-driving vehicles, fulfilling the promise of disruptive, connected and clean transportation systems.

More information: www.magment.de