Australian advanced materials technology company Talga Resources Ltd has achieved high levels of electrical conductivity in concrete by using an additive developed from the Company’s graphene-graphite research and development laboratory in the UK.

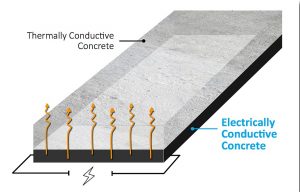

Talga Managing Director Mark Thompson: “The initial test results show that Talga’s graphene-enhanced concrete achieves such high electrical conductivity that it can act like the heating element of an electric stove” ([1], see Fig 1). “Talga’s successful tests follow work published by Exeter University [2] showing 146% improvement in concrete strength using graphene. They estimated that a 50% reduction of cement used for the same strength concrete would result in a 446kg/tonne reduction in carbon emissions by the cement industry, currently the third-largest industrial energy consumer and second largest industrial CO2 emitter in the world” [3].

The breakthrough offers substantial potential in existing and emerging industrial applications, particularly as concrete is the world’s largest construction material by volume.

Summary highlights are as follows:

- Initial tests show Talga’s graphene-enhanced concrete is highly electrically conductive – attaining 0.05 ohm-cm volume resistivity [see Technical Glossary]

- Adds potential ‘heating element’ function to world’s largest volume construction material (>5 billion tonnes p.a.)

- Current applications include: underfloor heating (replacing plumbed hot water based installations), anti-static flooring, EMI shielding, strain sensors and grounding/lightning protection

- Emerging application in solid-state heated roads for environmentally friendly way of clearing ice and snow from key transport routes and airports when compared to use of ploughs, corrosive salt, de-icing chemicals and wastewater treatment of runoff

- Future potential includes role in dynamic and wireless charging of electric vehicles while driving

The tests

The concrete samples were manufactured at Talga’s 100%-owned German process test facility and the Betotech (Heidelberg Cement Q&C) laboratory in Germany using industry standard cement with additions of Talga’s pristine graphene, graphite and silica-rich by-product of ore processing. The optimised formulation targeted high electrical percolation at low material concentrations and with potentially lower cost factors.

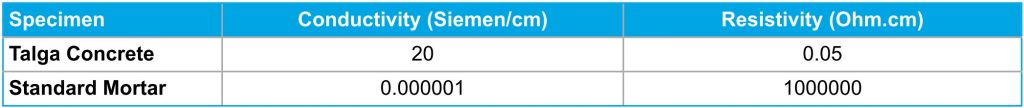

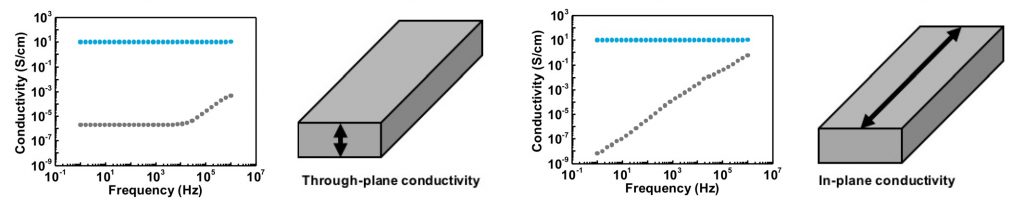

The samples were tested in-house, by a European industrial partner and further measurements were undertaken by Professor Ian Kinloch’s group at the University of Manchester (“UoM”). In the UoM study, the conductivity of samples was measured using electrical impedance spectroscopy in both through-plane and in-plane directions over a range of frequencies. For reference, a standard mortar (without Talga additives or aggregates) was used. A summary of results is shown below in Table 1 and Figure 2.

Fig. 2: Test data showing electrical conductivity of Talga concrete sample (blue) compared to reference mortar (grey) and stability of Talga material at a large range of frequencies. ©_TalgaResources

In summary the UoM tests recorded the Talga graphene enhanced concrete had high electrical conductivity (low resistivity) to 0.05 ohm-cm (Ohm is the measure of a material’s resistance to conduct electricity, the lower the better).

This rating compares to a general resistivity level of around 1,000,000 ohm-cm for the reference mortar at a similar dryness (the background level of moisture can affect electrical conductivity, so samples are measured at the same dryness).

The results have also shown the silica-rich by-product of ore processing is remarkably conductive in itself, tough and highly suitable for use in construction materials. Trial concrete products developed by Talga are targeting the innovative use of this material, thereby increasing potential economic benefits and sustainability of the future Swedish operation.

Applications

As concrete is effectively an insulator (does not conduct electricity) in a dry state, adding the function of high electrical conductivity has been a goal of material scientists for a long time.

Attempts typically relied on the addition of high loadings of magnetite (iron), steel fibres, synthetic and natural carbons (including graphite) but did not achieve high levels of performance. In addition the required (high) loadings of active materials tended to cause negative effects on cost, strength, corrosion and abrasion resistance, maintenance costs and weight.

The electrically conductive ‘graphene concrete’ has applications in current markets such as underfloor heating, where it can provide a long-term, low-maintenance alternative to plumbed hot water installations. As a ‘solid state heater’ the technology may enable more rapid, and environmentally friendly ways of clearing ice and snow from key transport routes and airports compared to the cost of ploughs, salt, de-icing chemicals and wastewater treatment of chemical runoff. The replacement of widely used salt: as a material cost, its transport and distribution, and its corrosive effect on road/bridge infrastructure and vehicles would be an emergent but high potential application for heatable concrete.

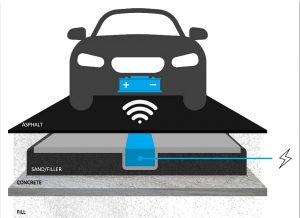

Fig. 3: Idealised concept of inductive (wireless) charging technologies for electric vehicles. ©_TalgaResources

In future, Talga will investigate the potential of the electrically conductive concrete for a cost effective role in enabling inductive (wireless) charging technologies for electric vehicles under dynamic (driving) as well as stationary (parking) conditions [4, 5] through the increased range of heating, sensing and other conductive concrete functions (See Figure 3).

Markets and next steps

The global concrete market exceeds 5 billion tonnes/year [6] and is worth over USD 450 billion/year [7]. Specialty concretes are a subset of this and while having no formal volume that may be attributed to a new product, Talga considers the market for conductive concrete is significant.

The Company currently has an MoU with the world’s second largest concrete manufacturer, Heidelberg Cement, focussed on thermally conductive concrete, but is free to explore other market opportunities. Talga is currently recruiting a European based commercial team, that will include construction sector and concrete market experience, to use these test results in commercialisation discussions with a range of industrial partners.

Further information: talgaresources.com

Talga Resources Ltd is an advanced material technology company enabling stronger, lighter and more functional graphene and graphite enhanced products for the multi-billion dollar global coatings, battery, construction and carbon composites markets. Talga has significant advantages owing to 100% owned unique high grade conductive graphite deposits in Sweden, a test processing facility in Germany and in-house product development and technology.

References

[1] talgaresources.com: TalgaGrapheneBoostsConcreteThermal Conductivity

[2] “Ultra high Performance Nano engineered Graphene – Concrete Composites for Multifunctional Applications”, D. Dimov et al, Advanced Functional Materials, 2018.

[3] Cement Sustainability Initiative, World Business Council for Sustainable Development, 2018.

[4] Location Planning for Dynamic Wireless Charging Systems for Electric Airport Passenger Buses, Helber et al “Energies”, 2018.

[5] Inductive Charging Through Concrete Roads, Beelden et al “European Road Infrastructure Congress”, 2016.

[6] Cement Market Forecast 2018-2023, IMARC Report 4715138, 2018

[7] World Cement & Concrete Additives Market, Freedonia Report 3358, 2016.

Related article:

– Wireless electric vehicles charging with magnetizable concrete (1. Mai 2018)

“Volume Resistivity” in detail on this website: omnexus.specialchem.com